Please fill in the short form below and we will get back to you shortly

With the shortage of natural sand for various reasons construction industry world-wide is adopting manufactured sand, also known as M-Sand, for concrete making purposes.

Manufacture of M-sand broadly involves the following steps to generate a product acceptable to the industry:

Industry normally adopts wet processing to produce manufactured sand, however with the rising demand dry process is also being lately promoted. Some of the technologies used in the dry processing of M-sand are:

Generically both these technologies suffer from a number of limitations in achieving a quality product. Some of these are:

Centrifugal air separators for fines separation have been available with the industry for long and has been used, inspite of low efficiency, in places where wet separation is not feasible because of water shortage. Manufacturers of dry centrifugal separators operate on the same principal of particle settling in air medium vide centrifugal force. The differences are in the details.

Dry screening has been used through ages for separation of particles based on size & shape. In a stream having a range of particle sizes, different screen openings can be used to separate any specific size of particles. The efficiency of the system depends on the following factors:

With typical dry screening, particle separation at 10 mm or lower is extremely difficult with high efficiency even in normal circumstances (<5% moisture) and becomes very poor at high moisture levels. At around 7-10% there is serious loss of efficiency.

In M-sand production process separation is also required at 5mm and 2.36 mm size in the primary stage (for concrete sand and plaster sand) and 0.075mm in the second stage and then mixing of particles is done. In some instances, the above two sand grades are not required and a single size range of -5+0.075mm is produced.

In bulk material screening high moisture content leads to stronger adherence between particles and this make it impossible for the particles to pass through the holes in conventional screening. Such cases require a higher force, may be 40-50G (G is the gravitational force) which cannot be achieved in screens where the frame is vibrated and the same is transmitted to the screening surface. To counter the loss of effectiveness some specific screening technologies are also available for the industry. One of these is the Flip-Flop screen.

Flip flow screens use a system of flexible screen panels that are alternately stretched and relaxed to impart motion specifically to the screen bed instead of relying only on mechanical vibration of the screen body. The throwing action can generate forces of up to 50G on the screen surface, preventing material from blinding the apertures. The screen body may be static or subjected to accelerations in the range 2 to 4G. The elastic screen panel is not only tensioned but additionally stretched up to 10mm. As a result, the shape of perforation is slightly changed and clogging and sticking of grain is prevented. This is an option which cannot be given by any conventional screening machine with inflexible screen panels.

Typical applications for Flip-Flop screens are:

Experience with two brands of Flip Flop screens shows that it is sufficient for fine screening / removal of filler (< 75µm) on very dry (<1% moisture) sand applications. However, if the material is so dry, it is possible to remove only fines < 100µm – 150mµ. As soon as the moisture is > 1% the cut point becomes coarser around 500µm – 700µm and there is serious loss of material. As stated, everything is related to the material (type, moisture, free flowing, not clayey).

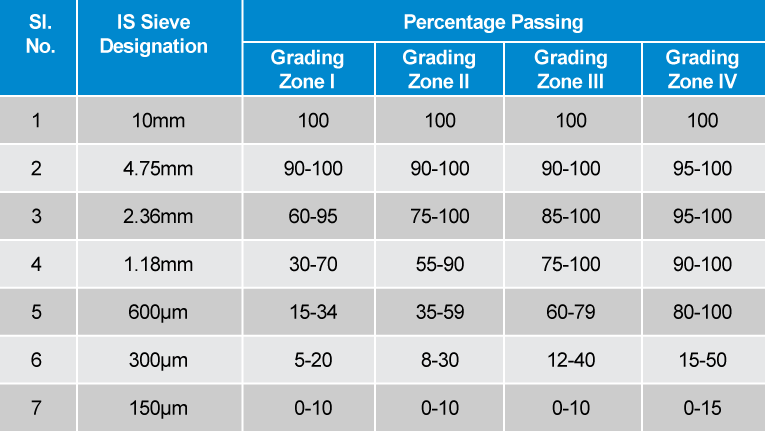

In this connection it would be in order to study the particle size distribution of different grades of sand as per IS 383. This is given below:

Table 1: Fine Aggregates

Normally Zone II sand is specified for concrete making in the construction industry. The level of <600 microns is a crucial factor and has to be maintained within the specified range as it effects the pumping of concrete. If due to inefficiency of the screening system in case of high moisture in feed, there is loss of -500+150-micron particle then the sand quality will not be acceptable to the users.

Even in the best of circumstances when moisture is <1% the cut point in the screen is 100-150micron and this will remove most of the <150micron which also needs to be maintained within a tight range in the sand product.

Inability to keep particle size distribution within range will make it difficult to achieve the Fineness Modulus (FM) values desired. It may thus be seen that Flip flop screen is not suitable for sand processing.

Additionally, the other disadvantages of Flip flop screen are

Combo patented wet processing technology takes care of all the above issues with very high efficiency and can be adopted to a wide variety of feed types in terms of size range and silt content. The specific advantages of the wet system are:

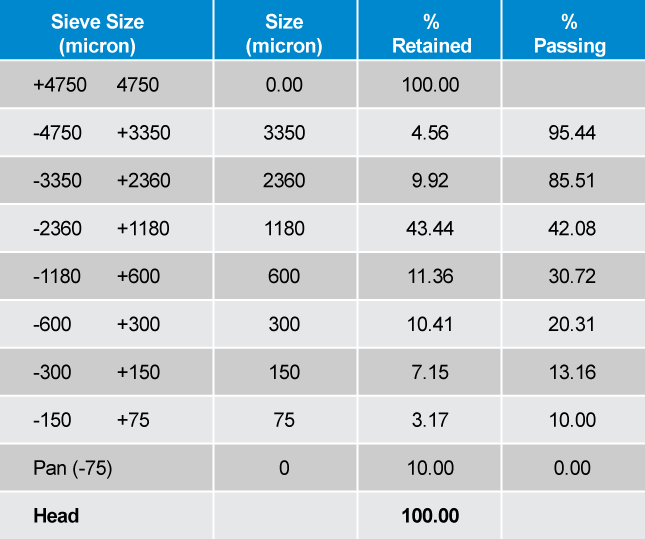

Table 2: Concept of mix & match explained for a particular application in the example below

The above is the size analysis of feed to a CDE Asia Limited washing plant. The desired product size is -5+0.075mm.

It may be seen that even if all <0.075mm is removed from the feed by wet washing the product will not meet desired Zone II specification given above particularly in 1,18mm and 600 micron sizes.

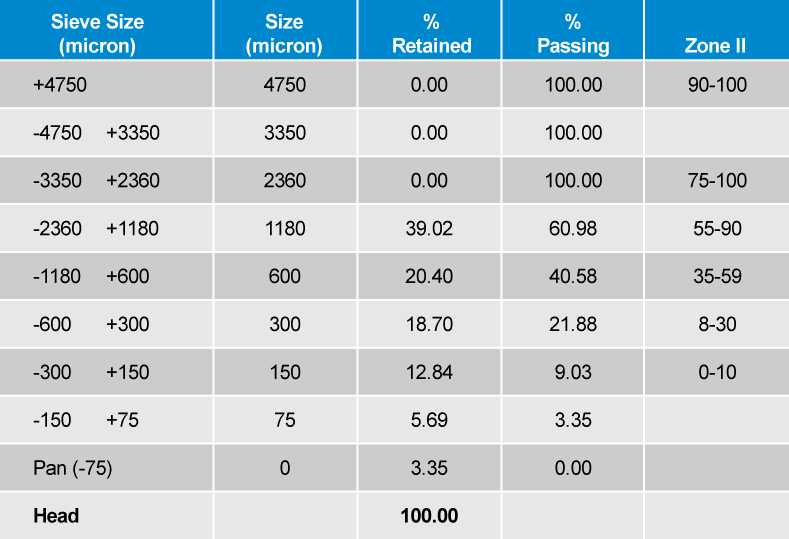

The plant was adjusted to mix and match the particle size during wet processing using special techniques and the following product was achieved which matches the specification.

Table 3: Zone II sand specification achieved using Combo

This is not possible in a dry screening or air classification system and screening systems.

It needs to be appreciated that simple removal of slimes like 75micron does not necessarily produce M-sand. The product has to match the standard over the whole particle size range for the purpose. For this it may be necessary to reject some particles, adjust proportion of other particle sizes and even adjust the proportion of slimes in the product. Only then does it become manufactured sand, M-sand.

CDE Asia Limited has enormous experience in M-sand manufacturing and has patented its technology after extensive R&D efforts. Our Combo is a green technology which takes care of local as well as environmental issues and has the following specific features: